Banks Industrial Restores Jersey City Hotel Chillers with Fast, In-Place Belzona Repair

Location:

Jersey City, NJ hotel overlooking Manhattan skyline.

Pain Point:

Corroded chiller tube sheets and end caps on a high-rise hotel’s 12th floor reduced cooling efficiency, risked AC failure, and posed a major challenge due to difficult access and rising demand.

Hotel’s Challenge:

When unexpected warm winter weather hit, the hotel needed a fast, durable solution to repair hard-to-access, corroded chiller components and avoid an AC outage during peak guest comfort demands.

The Challenge’s Impact On Day-to-Day Hospitality Operation:

Corroded chiller tube sheets reduce cooling efficiency and risk AC failure, threatening guest comfort, satisfaction, and hotel reputation—making timely restoration essential for maintaining positive reviews, repeat business, and uninterrupted hospitality operations.

Jersey City location overlooking the Manhattan skyline.

BIG Solution: Rapid Repair of Corroded Tube Sheets With Belzona Ceramic S-Metal Coatings

Corroded tube sheets, end caps and water boxes often go unnoticed until it's too late. Fortunately, BIG technicians have the ability to rapidly restore these components before they cause a breakdown and loss of comfort cooling.

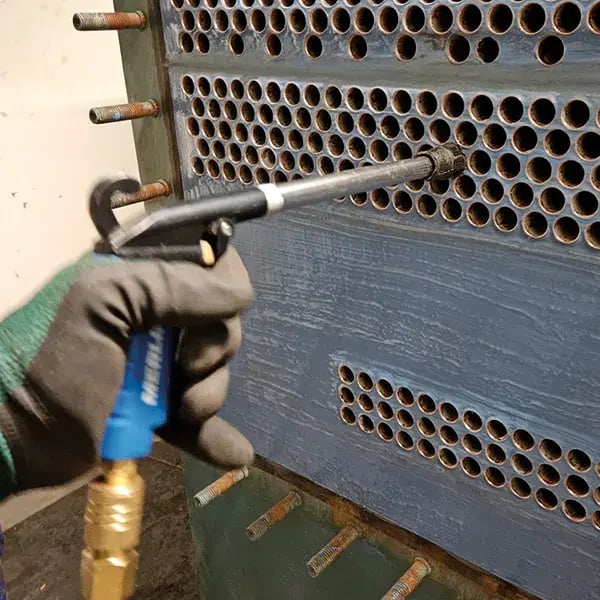

Over four days, BIG technicians meticulously grit-blasted rust, scale, and fouling from the corroded surfaces of two chillers, then rebuilt and protected the metal using Belzona 1341 Supermetalglide. This advanced, cold-applied epoxy coating offers long-term resistance to erosion, corrosion, and chemical attack, while also being VOC-free and safe to apply without hot work. The coating was applied in two contrasting layers (gray and blue) to ensure complete coverage and proper thickness, delivering maximum durability.

Despite challenges such as limited access on a high floor and the need for compressed air, BIG completed the work efficiently and safely. Within hours of curing, the system was back online, providing reliable cooling ahead of peak season demand.

Belzona’s high-performance materials not only halted corrosion but also extended equipment life, improved efficiency, and reduced turbulence by creating a smooth tube sheet face. This proactive repair prevented costly unplanned outages and ensured uninterrupted service for hotel guests.

By leveraging Belzona's proven polymer technology, Banks Industrial Group provided a fast, durable, and cost-effective solution that minimized disruption, safeguarded revenue, and delivered long-term HVAC asset protection.

The chiller tube sheet now lasts longer and works reliably thanks to Belzona's protective coating.

Step-By-Step Corroded Tube Sheet Restoration

Chiller end cap is removed to show tube sheet corrosion and increased risk of leaks and loss of performance.

Corks are used to seal the exchanger tubes, then corrosion and scale are removed to prep for coating.

Belzona 1121 repairs metal loss, followed by the first layer of Belzona 1341 Supermetalglide gray coating.

Second layer, Belzona 1341 blue coating ensures proper coverage and thickness to protect the tube sheet.

Corks are tapped into exchanger tubes after coating has cured (typically 4 hours at room temperature).

Tube ends are chamfered to remove any residual coating overlap that may decrease water flow.

All sunken corks are removed from within the heat exchanger tubes.

Compressed air is used to blow out any remaining dust and debris from within the exchanger tubes.

Completed tube sheet restoration and protective coating ready for service after final inspection.

Chiller End Cap Restoration

Corroded inlet/outlet end cap with division bar.

The restored condenser inlet/outlet end cap.

Belzona coating provides long-term protection.

For more information about our tube sheet corrosion repair and protective coating service, and other industrial solutions, email our team or call us today at: 856-687-2227.