Heat Exchanger Repair and Coating Services

Tube sheets, end caps, water boxes, and other heat exchanger components are susceptible to damage from corrosion and erosion. These damages can decrease system efficiency, increase operating costs, and eventually cause a complete breakdown.

Heat exchanger repair and coating services from Banks Industrial Group (BIG) can quickly solve your deterioration issues and provide long-lasting protection against future damage. BIG can also apply protective coatings to new or refurbished components to prolong service life.

This video highlights the ease of Belzona HVAC chiller repair and protection systems.

Need Chiller Repair or Heat Exchanger Repair?

| BIG Heat Exchanger Repair and Coating Service Benefits | |

| Minimal Downtime | BIG’s rapid equipment repair services minimize downtime and lost productivity |

| Extend Service Life | Long-term corrosion protection extends asset service life |

| Durable Repairs | Repairs are durable and provide long service life |

| Cost-Effective | BIG’s rebuild service costs far less than replacement |

| Restored Ability | Repairs restore lost efficiency and improve reliability |

| Eliminate Corrosion | Protective coatings eliminate galvanic corrosion |

| Coating Options | High-temp and chemical resistant formulations are available |

| No Hot Work | Epoxy coatings are cold curing—no hot work required |

| Safe Formulas | Epoxy coatings are safe and free of VOC materials and solvents |

Corrosion of Tube Sheets, End Caps, Water Boxes, etc. Decreases Efficiency and Increases Risk of Breakdown

Corrosion, erosion, and microbial growth cause HVAC systems to experience numerous problems, including:

-

Decreased efficiency

-

Increased operating cost

-

Reduced reliability

Without professional maintenance, systems will eventually break down. The resulting downtime causes loss of productivity for industrial processes and revenue losses for businesses without comfort cooling.

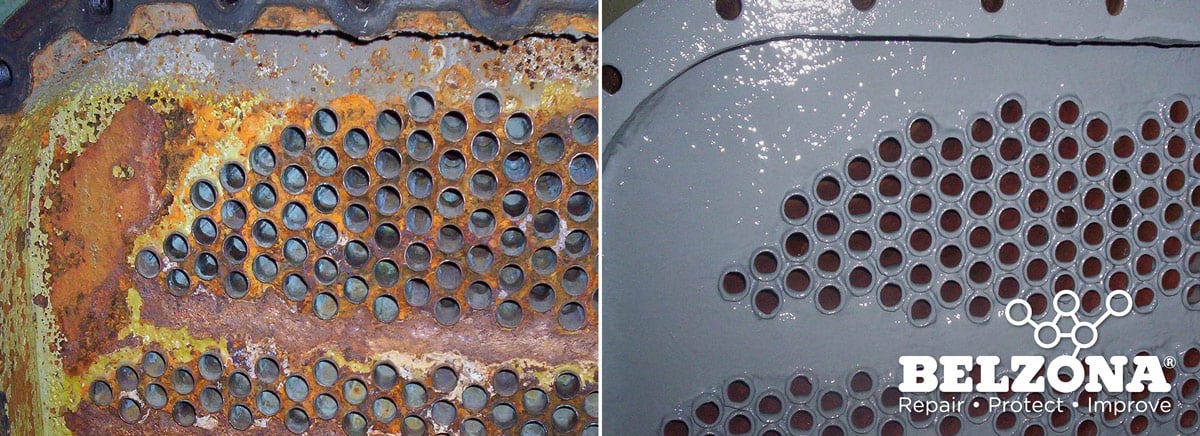

Belzona Coatings Restore and Protect Damaged Heat Exchanger Components to Prolong Service Life

Banks Industrial Group uses Belzona metal repair polymers to give you the ability to easily repair and protect damaged chiller, heat exchanger, and boiler components. Application is quick and often completed within two days. Repairs show a high return on investment when compared to either:

-

Lost efficiency and productivity due to system breakdown—or—

-

High-priced replacement machinery

After application, our durable repairs can protect your tube sheets, end caps, and water boxes for years to come, reducing your HVAC maintenance costs. If you see the effects of corrosion during an inspection, don’t ignore it—call BIG and schedule professional service.

For insight on the proper planning, preparation, and application of protective coatings, see our post: Why Protective Coatings Fail.

Heat exchanger tube sheets can be quickly rebuilt using Belzona metal repair.

This heavily corroded end cap was easily restored for added service life.

Water box repaired and protected with Belzona polymeric materials.

Corroded Tube Sheet Coating Repair Case Study

Read about the tube sheet restoration of corroded chillers on the 12th floor of a Jersey City hotel. Banks Industrial Group provided a fast, durable, and cost-effective solution that minimized disruption, safeguarded revenue, and delivered long-term HVAC asset protection.

Banks Industrial Group Is Your Home for Heat Exchanger Repair and Coating Services

In addition to heat exchanger repair and coating services, Banks Industrial Group offers repair of other HVAC components as well, including:

-

Damaged fan blade rebuild and protective coating

-

Worn fan shaft and bearing rebuild

-

Seam sealing and corrosion repair of leaky HVAC ducts

-

Exterior HVAC duct insulation service

BIG’s heat exchanger repair and coating services are a cost-effective solution to HVAC component deterioration. We can perform the application for you, or train your staff to perform it.

Banks Industrial Group specializes in above-ground storage tank insulation, protective coatings, concrete, and related maintenance and repair services. Our innovative, and cost-saving solutions help keep your facility running efficiently. For more information about our heat exchanger repair and coating services, contact our team today by calling 856-687-2227.