Anti-Slip Coating Solves Problem of Slippery Dock Levelers

Environment:

Warehouse loading dock

Pain Point:

Slippery diamond plate dock levelers create a safety hazard for pedestrian and forklift traffic, especially during inclement weather.

Warehouse’s Challenge:

Conventional anti-slip paints and tapes applied to solve this problem would wear off within a few months due to forklift and pallet jack traffic scraping against the dock leveler plates.

The Challenge’s Impact On Day-to-Day Warehouse Work:

Frequent reapplication and maintenance of grip systems drove costs and eroded efficiency. Slippery conditions created a constant safety hazard.

BIG Solution: Belzona Epoxy Grip Aggregate & High Wear Urethane Top Coat

This anti-slip coating solution offered an outstanding grip, ensured a significant reduction in slip and fall incidents, and demonstrated remarkable resilience against impact and abrasion. Unlike traditional adhesive strips that are susceptible to peeling and wear, this exceptional epoxy-based coating showcased a prolonged service life without the need for frequent replacements or maintenance.

One of the advantages of this specialized epoxy coating was its rapid application and curing process. The expedited epoxy coating application ensured that the loading dock was fully operational within 48 hours, minimizing downtime and maximizing productivity. This swift and effective solution prioritized employee safety and optimized operational efficiency.

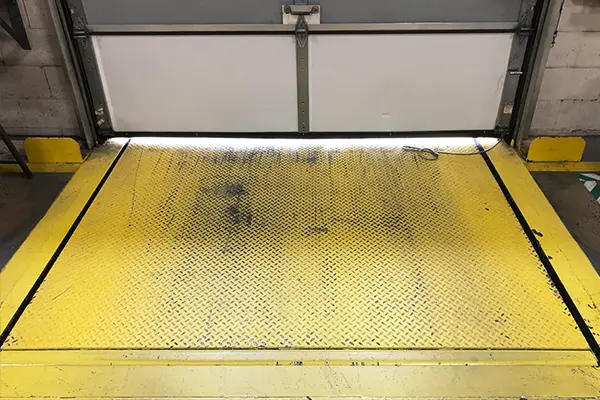

1. The once reliable non-slip coating on this dock leveler has deteriorated prematurely, resulting in a dangerously slippery surface when wet.

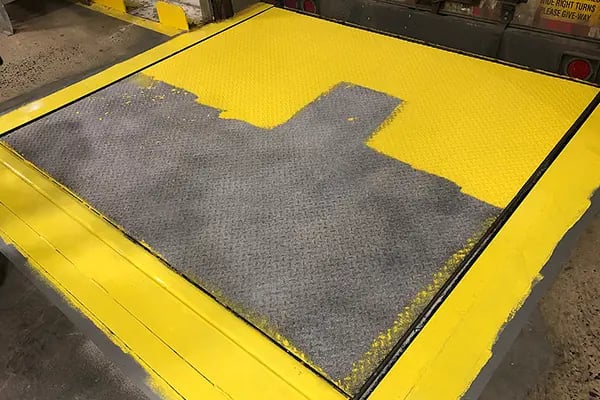

2. Surface preparation involves using shot blasting techniques to remove the previous coating and applying a high-quality primer.

3. Applying the powerful combination of Belzona 4911 epoxy and grip aggregate for maximum effectiveness.

4. Our high-performance urethane top coat is specially formulated to resist the damaging effects of UV rays.

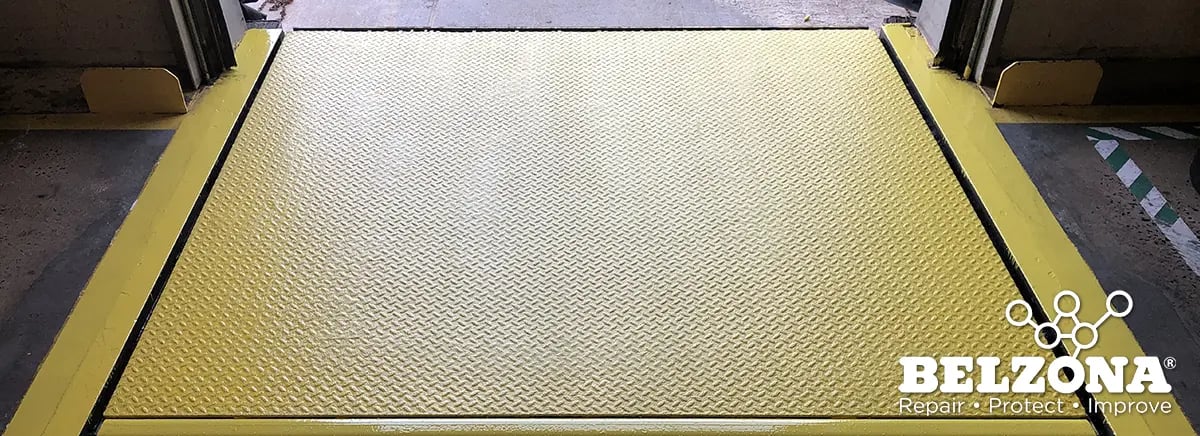

After 18 Months

After 18 months of continuous service, we present the same dock, showcasing its impressive durability. Our esteemed client shared their satisfaction, stating, “This loading bay sees 12-15 trucks per day and is loaded and unloaded with pallet jacks that consistently scrape the ground. This safety coating is holding up better than anything we’ve ever used.”

For more information about our dock leveler anti-slip coating service, and other industrial solutions, contact our team today by calling 856-687-2227.