The inspection of storage tanks and piping in bulk liquid storage terminals is a critical maintenance activity. Steel tanks and pipes experience wear due to the abrasive nature of liquids and natural corrosion. To comply with regulations, API 653 and API 570 standards require that certified inspectors perform external inspections every five years and internal inspections of tanks every ten years.

When tanks or piping are insulated, inspecting them poses challenges. Insulation can obscure critical areas, making it difficult to assess wall thickness or detect corrosion. To address these challenges, inspection ports can be installed to provide access points for regular, non-destructive testing (NDT). These ports allow inspectors to measure wall thickness without removing large sections of insulation, ensuring consistent and accurate tracking of wall degradation over time.

Key Benefits of Inspection Ports

Inspection ports offer the following advantages for tank and pipe maintenance:

- Access to Steel Surfaces: Inspection ports provide easy access to the steel surface of a tank or pipe for metal thickness measurements. Despite being covered by insulation, these ports make it possible to conduct regular checks.

- Predictive Maintenance: With consistent measurements, facility owners can predict corrosion rates and estimate equipment life expectancy. This enables timely repairs to prevent equipment failure.

- Quick Reinstallation: After each measurement, the insulation plug and the silicone rubber port plug are reinstalled for a watertight seal, maintaining the integrity of the insulation system.

Factors to Consider When Choosing an Inspection Port

When selecting an inspection port, several factors must be considered to ensure proper functionality:

- Temperature Compatibility: The inspection port must match the service temperature of the line. Ports come in various styles and temperature ratings, and selecting the wrong port could lead to damage. For example, failing to replace the protective insulation in the port could result in the silicone rubber plug being damaged by heat.

- Quality of the Port: It is essential to choose a high-quality inspection port that fits securely against the insulation cladding. Over time, polymers in lower-quality ports may shrink due to temperature exposure, leading to improper sealing. In some cases, the port may detach from the insulation cladding, allowing moisture to enter and compromise the system.

- Durability Features: Look for an inspection port with an attached lanyard to prevent the silicone rubber plug from being lost during inspection. This small feature ensures that after the inspection is complete, the plug can be easily reinserted into the port, maintaining a secure, watertight seal.

Cost Considerations for Inspection Ports

The cost of inspection ports varies depending on the product's quality and the specific temperature requirements. Inspection ports with aluminum flanges and silicone caulking for sealing tend to be more reliable and durable.

- Standard Sizes and Costs: The most commonly sold inspection port has a plug diameter of 2.5 inches and a temperature rating of up to 500 degrees Fahrenheit. This type of port typically costs around $15.00, with larger and higher temperature-rated ports costing more.

- Installation Costs: It is important to note that labor costs for installing inspection ports often exceed the cost of the port itself. As with most maintenance items, the expense of labor can be a significant factor when budgeting for installation.

Ideal Placement for Inspection Ports

Inspection ports should be installed in locations where the greatest degradation of steel wall thickness is expected. For example, these areas might include places where corrosion is likely to occur due to moisture penetration or where the flow of materials exerts the most wear on the tank or pipe walls. For a 50-foot diameter tank, the recommended placement includes:

- Tank Base: Three ports, located 1, 3, and 5 feet off the tank chime, in four locations around the tank.

- Sidewalls: 24 ports, placed in 2-foot increments up the sidewall near any steps.

- Under Steps: If the tank has steps welded directly to it, 24 ports should be installed under the steps in 2-foot increments. Welded steps create additional areas for moisture penetration and corrosion.

- Tank Roof: Four ports, arranged in a straight line from the tank edge to the center, in eight locations around the roof.

For piping, API 570 requires inspections at elbows and tees, which are the areas most prone to erosion and wear. Inspection ports should be installed:

- Before and After Elbows and Tees: These configurations tend to experience the most wear, so ports should be installed on the straight sections of pipe immediately before and after each bend or junction.

Installation Process for Inspection Ports

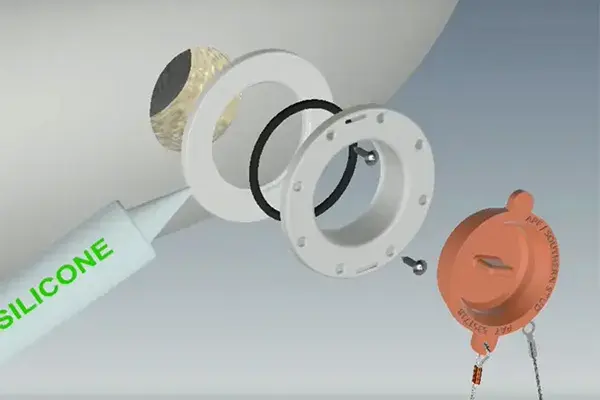

Installing an inspection port is a straightforward process that, when done correctly, ensures long-term functionality and reliability. Following these steps can help achieve a secure installation:

- Prepare the Area: Begin by cutting the aluminum insulation jacketing with a knife or tin snips, or use a hole saw with a battery-powered drill to make the necessary opening.

- Remove Insulation: Cut away the insulation beneath the jacketing to create a path to the steel surface of the tank or pipe.

- Apply Silicone Sealant: Apply a bead of silicone sealer to the back of the aluminum flange of the inspection port. This ensures a secure, watertight fit against the insulation cladding.

- Attach the Flange: Screw the aluminum flange to the insulation cladding, using one of the screws to secure the silicone plug lanyard to the flange. This lanyard prevents the plug from being misplaced during future inspections.

- Insert the Plug: Insert the protective insulation and the silicone rubber plug into the port to complete the process.

For future inspections, we recommend attaching ID tags at each inspection port location to ensure consistency and ease of access for inspectors.

Conclusion

Inspection ports offer an effective solution for overcoming the challenges of inspecting insulated storage tanks and piping systems. By providing easy access for non-destructive testing, these ports allow facility owners to conduct regular inspections without removing large sections of insulation. With proper installation and the use of high-quality materials, inspection ports can remain in place for many years, maintaining the integrity of both the insulation system and the equipment being inspected.

For any facility that requires regular monitoring of tank and pipe integrity, inspection ports are a cost-effective, reliable tool that supports long-term equipment health and compliance with API 653 and API 570 standards.