Warehouse Guard Rails and Installation Services

Physical barriers are key to creating safe and efficient warehouse facilities. Barriers—such as pedestrian guard rails, traffic barriers, and forklift curb guards—enhance workplace safety by:

- Protecting workers from potential dangers

- Shielding equipment from collisions and other workplace accidents

- Fortifying structures against impact damage

To enhance workplace safety, Banks Industrial Group sells and installs A-SAFE warehouse guard rails. Suitable for both warehouses and other industrial facilities, A-SAFE guard rails use state-of-the-art polymers called MEMAPLEX and multi-component engineering for superior performance and longevity. A-SAFE’s design enables the barriers to flex and fully recover after repeated impacts, leading to fewer repairs, lower annual maintenance, and greater worker protection.

Need Guard Rails?

Below, we explore the benefits of A-SAFE warehouse guard rails:

| The Benefits of A-SAFE Warehouse Guard Rails | |

| Proven Safety | Scientifically engineered and tested for safety |

| High Performance | 80% impact absorption |

| Bounce Back | Flexible design absorbs forklift hits and returns to shape after multiple impacts |

| Pedestrian Protection | Separates forklift traffic to reduce accident risk, safeguard, operations and save lives |

| Asset Protection | Protect equipment and structures from vehicle collision, preventing costly damage and downtime |

| Driver Direction | Define traffic routes and provide visual guidance to drivers |

| Repair Savings | Impact energy is dissipated, reducing damage to the guard rails, floor and forklift |

| Floor Protection | A-SAFE barriers absorb and disperse impact forces to protect anchors and prevent floor damage |

| Maintenance Savings | Self-colored, UV stable polymer does not rust and won’t ever need a new paint coat |

| Cold Storage | A-SAFE barriers withstand impacts without cracking in extreme temperatures down to -22°F |

| Surface Resilience | Surface is food safe, hygienic sealed, wipe clean and water resistant |

| Expert Consultation | A consultation with BIG will uncover the ideal barrier solution for the vehicles at your facility |

| Convenient Installation | Fast, safe installation with minimal disruption by our factory certified crews |

Antiquated Steel Barriers Drive Up Maintenance and Repair Costs

Warehouse operators typically use steel barriers to protect their assets and infrastructure. Over time, forklift drivers inevitably hit these barriers again and again. To remain functional after repeat impacts, steel barriers must be professionally repaired and serviced.

If a steel guard rail is hit hard enough by a forklift, not only does it need to be replaced, but collision will also damage the floor where the rail was bolted. In these scenarios, facility operators must contend with:

- Loss of product

- Vehicle damage

- Operator injuries

In addition to these cost factors, the resulting downtime will also negatively affect your bottom line. Unplanned downtime has a ripple effect—it can significantly increase costs, threaten production goals, and often causes downstream problems that magnify its consequences.

Read more about the cost of ignoring repairs.

Flexible Warehouse Guard Rails from A-SAFE Create Long-Term Savings

A-SAFE warehouse guard rails offer better protection and longer lifespans than steel barriers. Flexible polymer is three times stronger than steel and absorbs 80% of impacts. A-SAFE’s polymer construction enables the guard rails to rebound to their original positions for continued protection. A combination of the internal mechanical design and the flexible polymer also redirects the impact away from the floor anchors, significantly reducing the chance of floor damage during a collision.

A-SAFE barriers also protect forklifts from damage. Metal guard rails deflect impacts and shield what is behind them at the expense of the forklift and the guard rail itself. Once a metal guard rail is hit, not only do you have to repair or replace the barrier, but you have to fix the vehicle as well.

Altogether, A-SAFE guard rails save you from costs associated with the following:

- Downtime

- Barrier replacement

- Vehicle damage

- Floor repair

- Equipment/infrastructure damage

- Human injury

In addition to these savings, no repainting is required. The self-colored yellow polymer hides scrapes for lasting visibility. Overall, you can expect a return on investment in just 19 months or less from reduced maintenance needs, lower repair costs, general incident prevention, and downtime avoidance.

Read more about the appropriate physical barriers for your needs.

Modular Guard Rail Configuration Options

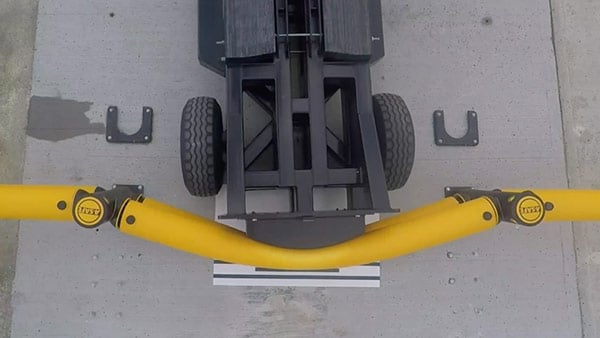

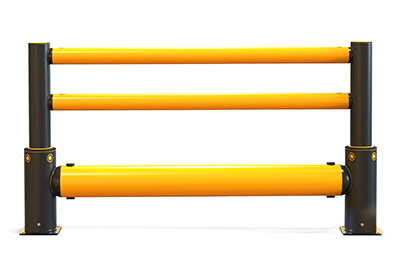

Forklift Guard Rails

Impact Rated for 13,000lb. @ 6mph

Forklift/Pedestrian Guard Rails

Impact Rated for 13,000lb. @ 6mph

Double Forklift Guard Rails

Impact Rated for 17,600lb. @ 6mph

Double Forklift/Pedestrian Guard Rails

Impact Rated for 17,600lb. @ 6mph

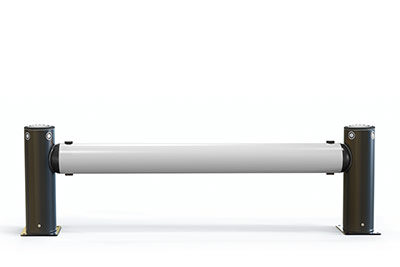

Pedestrian Guard Rails

Impact Rated for 7,000lb. @ 5mph

Cold Storage Forklift Guard Rails

Impact Rated for 18,400lb. @ 6mph

Cold Storage Forklift/Pedestrian Guard Rail

Impact Rated for 18,400lb. @ 6mph

Cold Storage Pedestrian Guard Rails

Impact Rated for 10,200lb. @ 5mph

Forklift Curb Guard

Impact Rated for 5,600lb. @ 4mph

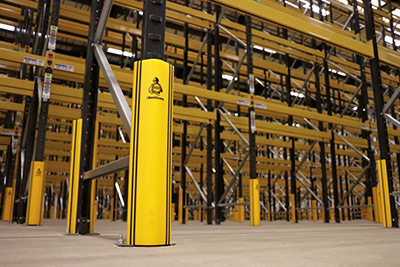

Column Guard Rails

Impact Rated for 7,000lb. @ 5mph

Heavy Duty Column Guard Rails

Impact Rated for 12,000lb. @ 6mph

Parking Garage Guard Rails

Impact Rated for 4,400lb. @ 10mph

A-SAFE SPECIFICATION FAQs

How many times can you hit an A-SAFE barrier before they break? What is the typical longevity?

The answer is… it depends. The longevity is highly dependent on the environment and the application area. Wear and tear may begin to show after 2 years depending on the number of impacts to the barrier. Obvious signs might be stretch marks if the barrier is hit in the same spot consistently over time. Without consistent impacts, the longevity is a lifetime. That said, if you have one particular weak spot, the individual rail or section can be replaced by themselves as a result of the modular design. There are a few regular preventative maintenance checks you can do to extend or maintain the lifetime - namely checking the torque settings on the anchor bolts to 50kg (110 lbs).

How fast can a standard forklift hit the barrier and still be safe?

The answer depends on the combined size of the forklift and load, plus the angle of impact to the barrier. Direct hits at 90° have greater impact than glancing blows. The manufacturer recommends a governed speed of 6 mph although some operators choose to not put a limit on their forklifts. That said, the product is not indestructible, but an A-SAFE barrier can withstand 12,000 lbs at 6 mph and 90° impact.

How much stronger than steel are A-SAFE barriers?

A-SAFE flexible polymer barriers are three times stronger than steel and can absorb up to 80% of impact.

How do A-SAFE barriers prevent your floor from being damaged?

We use expansion anchors. The anchors between the plate and the post will sheer off at the wear collar if the post is impacted with enough force. The separation occurs between the base plate and the post if hit hard enough, preserving the base plate into the floor.

Can I secure a bollard or rail to asphalt?

Yes, but make sure you alert us to the condition prior to purchase and installation as it requires a special anchor that may cost a little bit more than the standard anchor.

Will the base plates corrode?

No, the base plates are made of galvanized steel. Stainless steel base plates are also available.

What temperatures are the barriers good to?

Standard products work between 14°F and 122°F, while the cold storage product functions between minus 22°F up to +32°F.

Will A-SAFE flexible barriers maintain their color outdoors?

Yes, they are UV protected and tested to ISO 4892-3.

What colors do they come in?

Standard rails come in black and yellow. Cold storage rails are black and blue. Gray rails are available as well. All products can be ordered in a custom color with additional cost and production time.

How do I integrate a gate into the protective scheme?

Swing gates can be integrated into guard rail schemes but swing gates offer no energy absorption. They simply separate traffic and allow thru-traffic access. Dock gates however do flex and offer energy absorption.

What is the difference between mFlex, eFlex, iFlex and Atlas?

We sell barriers that are “fit for purpose” and we utilize products based on the impact and energy rating required by the customer’s operations and environment. When heavier forklifts or powered vehicles are present, iFlex or Atlas rails are required, and the “fit for purpose” is really determined by the number of rails applied to the task.

mFlex products absorb the least impact and are suitable for pallet jacks protecting walls. They sit on the floor and can be trip hazards if placed improperly. eFlex is suitable for separating pedestrian traffic and carries a lower energy rating. iFlex and Atlas carry the same energy rating but are configured slightly differently. These are heaviest duty rails and can absorb impacts from larger and/or faster vehicles. If a forklift or larger is present, iFlex should be utilized. Airports or outdoor applications should utilize Atlas.

SAFETY COMPLIANCE FAQs

What OSHA regulations exist around safety barriers?

The simple answer is none, comprehensively, for guard rails. OSHA still maintains the “general duty” standard which is a catch all for employing appropriate safety products. That said, the EU maintains a standard known as PAS 13, that sets standards for guard rails and their performance.

Who tested the A-SAFE barriers?

A-SAFE tests the barriers in the United Kingdom. Results are independently verified by German testing firm TÜV-NORD.

Are A-SAFE flexible barriers safe to use in a food processing facility?

Yes. All products are hygienically sealed, and the product complies with EU and FDA food contact regulations.

ORDERING FAQs

How long will it take to get a quote?

Since the barriers are designed and verified to be fit for purpose, it takes 24 to 48 hours during normal business days to receive a quote.

How much more do A-SAFE polymer guard rails cost than steel?

Typically the cost runs about 30% more than steel safety barriers, but you get return on investment the first time a vehicle impacts your barrier.

What’s the warranty on A-SAFE flexible barrier products?

Every product comes with a 12-month manufacturer’s defect warranty. If you purchase factory-authorized installation services, the warranty can be extended to 3 years. If customers do self-installation, a factory authorized inspection can be purchased to extend the warranty to 2 years. Defects in installation can be identified relatively easily within the first day by a trained professional.

INSTALLATION FAQs

Can I install them myself?

Yes, customers can install these themselves. We provide installation instructions, with special care paid to install of the anchor bolts.

Do you offer install training? How many people does it take to install?

Yes, we can train your crews to install the product. The number of people required to install the product depends on the size of the job, but every installation should use at least three people.

How much of a gap should be between the A-SAFE guard rails and the protected asset?

A minimum 18" should exist between the guard rail and the protected asset.

Save Money and Protect Your Workers with A-SAFE Warehouse Guard Rails from Banks Industrial Group

Banks Industrial Group provides single-source service for the sale and installation of A-SAFE warehouse guard rails and safety barrier systems. We are safety-oriented, ISNetworld-certified A+, and fully insured to reduce your risk. If desired, we can also train your staff to perform the installation.

Banks Industrial Group specializes in above-ground storage tank insulation, protective coatings, concrete, and related maintenance and repair services. Our innovative, and cost-saving solutions help keep your facility running efficiently. For more information about our A-SAFE warehouse guard rails, and other industrial solutions, contact our team today by calling 856-687-2227.