Floor Expansion Joint Repair

Replace damaged floor joint cover plates and deteriorated concrete

Banks Industrial Group offers specialized "Smooth Ride" repair of damaged floor expansion joints between concrete slabs within hospitals, long-term care, pharmaceutical and food / beverage processing facilities. Our solutions use fast curing polymeric materials for rapid installation and long service life. Benefits include:

-

Replace damaged floor joint covers with a long-term solution

-

Seal out risky mold and microbial growth that occur when water seeps under metal joint covers

-

Withstand high load point stresses and impacts from gurneys and hard wheeled carts

-

Eliminate trip hazards and smooth out bumpy patient rides due to damaged joint covers

-

Polymeric materials provide a smooth, level surface

-

Elastomer grips to concrete and metal and elongates 1000% to accommodate expansion movements without compromising the water tight seal

-

Safe, cold applied materials do not require hot work and are VOC free

-

Fast-curing for minimal downtime

Need Floor Expansion Joint Repair?

Request an estimate or consultation.

What can go wrong with a hospital expansion joint?

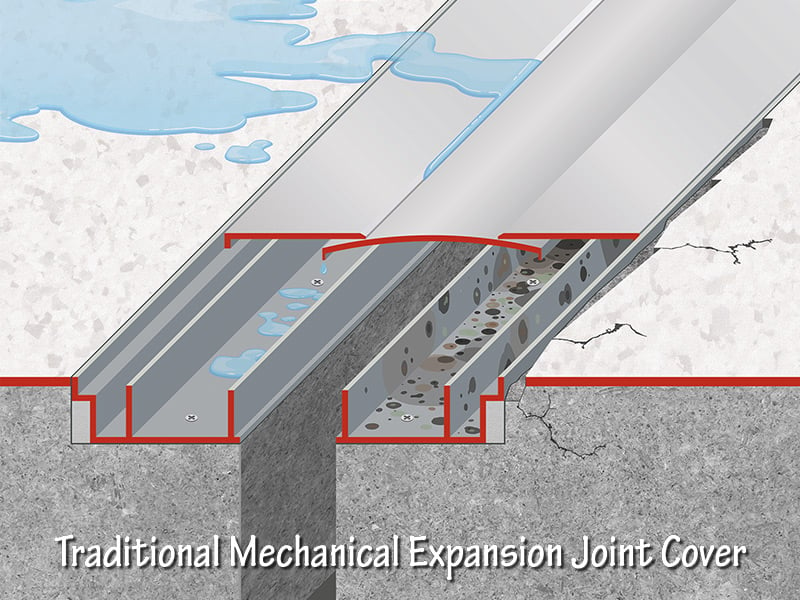

Concrete expansion joint covers are not watertight. Over time moisture and filth accumulate and create a hidden environment where mold and microbial growth flourish. This produces a potential health risk for hospitals and medical centers. Slab edges deteriorate from foot and wheeled traffic and worsen the problem. Eventually, trip hazards develop when the joint covers begin to loosen and bend. This also causes a bumpy, uncomfortable ride for patients on gurneys or wheelchairs, and results in spills from transport carts.

How does BIG fix broken floor expansion joints?

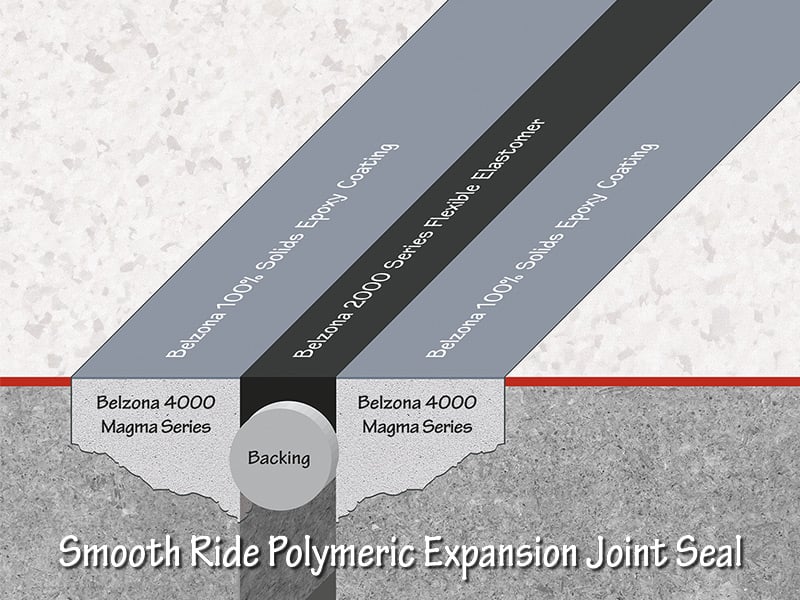

We provide a specialized repair suitable for high-traffic corridors, halls and surgical rooms. Our Belzona Smooth Ride system uses durable polymeric repair mortar combined with flexible elastomer to replace worn out movement joints. The result creates a flush and smooth joint impervious to water and eliminates microbial growth in the joint and trip hazards. The Smooth Ride elastomer flexes and accommodates expansion movements for decades of service life.

Where is the Smooth Ride repair applicable?

Our Smooth Ride system is suitable for use in hospitals, healthcare, long-term care, pharmaceutical, and food and beverage processing facilities. These are places where indoor air quality, mold and infection risk are of concern.

How is the Smooth Ride system installed?

First, we remove damaged concrete, broken components, dirt and debris. Next, we clean and prepare the the surface. We then apply Belzona Magma-Quartz to replace deteriorated concrete with a durable material that can better withstand impact and load point stresses. Afterward, we insert a backer rod into the joint and apply a specialized elastomer to seal the gap. This elastomer exhibits up to 1000% elongation and easily handles any thermal or physical movements. Finally, we apply a protective coating to keep the materials below clean.

How Can We Help You?

BIG will repair and seal your damaged building expansion joints. Please contact us today for more information or to schedule service.