External Tank Coating Services

Banks Industrial Group’s (BIG) external tank coating services help you reduce downtime, extend asset service life, and avoid replacement costs. We use specialized Belzona coatings explicitly designed to protect against salt water, corrosion, and chemical exposure. We can match the coatings to suit your specific requirements.

Need Tank Coating?

| BIG External Tank Coating Services Benefits | |

|---|---|

| Extended Asset Service Life | Our external tank coating services protect against salt air, acid rain, chemical exposure, and corrosion, avoiding replacement costs. |

| Reduced Downtime | BIG’s external tank coating process avoids production downtime. Our expert crews use fast-curing materials to ensure a speedy return to service with minimal downtime. |

| Easy Application | We use a fast spray application over large surface areas. |

| Reduced Safety Risks | Our cold-curing materials eliminate hot work, ensuring safe and easy maintenance. |

| Electrostatic Discharge | Our static dissipative formulations transfer surface build-up of electrostatic charge away from hazardous areas such as hydrocarbon tanks and grain silos. |

| Corrosion Prevention | Our liquid anode formulations prevent cathodic corrosion in harsh marine and industrial environments. |

| Surface Prep | We perform surface prep to remove old coatings and areas of corrosion, repairing metal damage where needed. This ensures proper coating adhesion for long service life. |

External Tank Coating Services Using Premium Belzona Compounds

We use Belzona's epoxy repair composites and coatings, which provide robust external protection for storage tanks and process vessels. Belzona’s coatings protect the tank wall from atmospheric corrosion and corrosion under insulation. Application is fast, surface tolerant, and chemically resistant.

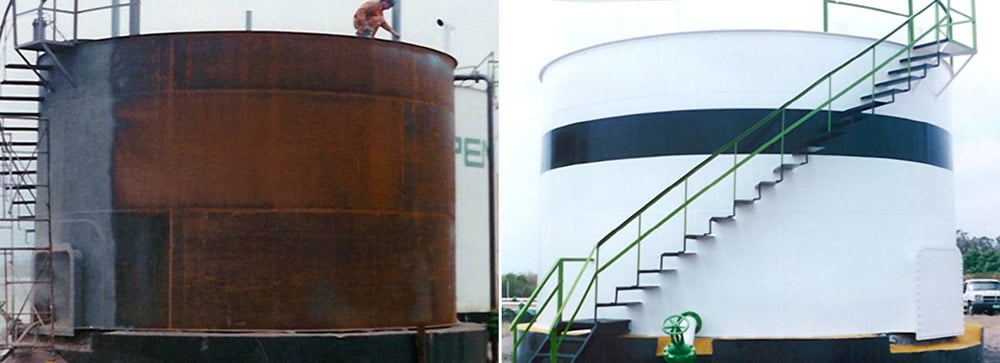

External Tank Corrosion Problem/Solution Example

Problem: External tank corrosion

Corrosion can occur on the exterior of storage tanks as a result of adverse weather conditions and harsh working environments. Leaving corrosion damage untreated can cause structural damage and wall defects, resulting in leakage and a loss of containment, with costly consequences.

The repair of storage tanks can disrupt the business, so the following challenges need to be addressed:

- Protect the tank against salt air, acid rain, chemical exposure, and erosion

- Provide a long-term corrosion barrier

- Give the tank an aesthetically pleasing appearance

- Ensure ease and speed of application, particularly over large areas

Solution: Application of corrosion-resistant coatings to protect tank surfaces

Using proven Belzona coatings and repair composites, BIG can repair corroded storage tanks and protect them from corrosion. Our solutions provide corrosion and stain resistance to the exterior of storage tanks. This means that they will be protected from corrosion over the long term, can be easily cleaned, and have an aesthetically pleasing appearance.

Due to the ease and speed of BIG’s applications, your downtime will be significantly reduced, and production disruption kept to a minimum. Our coatings and composites are resistant to a range of conditions and provide excellent protection against corrosion and environmental degradation. We also provide storage tank repair services, including:

- Tank-base sealing using solvent-free coatings that prevent water from getting under the tank while allowing moisture to escape

- Composite patches to repair external tanks according to international standards and designed for pressure-retaining patch repairs

- High-adhesion epoxy composites to restore tank integrity by plate bonding

BIG applied a protective coating to shield these silo tanks against a corrosive operating environment.

Banks Industrial Group specializes in internal and external tank coatings services, above-ground storage tank insulation, protective coatings, concrete, and related maintenance and repair services. Our innovative and cost-saving solutions help keep your facility running efficiently. For more information about our external tank coating services and other industrial solutions, contact our team today by calling 856-687-2227.