Secondary Containment Coatings

Repair. Protect. Comply.

Secondary containment is your last line of defense against environmental contamination and workplace exposure. When these areas deteriorate, they put your facility, employees, and compliance record at risk. Banks Industrial Group (BIG) specializes in restoring damaged containment structures and applying Belzona’s advanced protective coatings to stop acids, caustics, and other aggressive chemicals from attacking your concrete. The result is long-term protection that reduces risk, extends service life, and keeps your operations moving safely and efficiently.

What We Like About Belzona Secondary Containment Solutions

BIG uses premium Belzona repair mortars and coatings to refurbish and protect a wide range of containment structures including dikes, bunds, splash pads, channels, drains, sumps and loading/unloading areas. Whether the challenge is chemical splash damage, settlement cracking, or worn surfaces creating unsafe conditions, our team delivers tailored solutions that restore integrity and improve safety.

-

Minimal Downtime: Fast-curing formulations minimize downtime, often returning containment areas to service within hours instead of weeks required for traditional concrete repairs

-

Superior Protection: Exceptional chemical resistance shields concrete from acids, caustics, and solvents, even under high-temperature or immersion conditions, extending containment service life

-

Strong: High-strength mortars rebuild deteriorated concrete with outstanding compressive strength and impact resistance, restoring structural integrity without costly reconstruction

-

Tenacious Bond: Strong adhesion to concrete, brick, steel, and stone prevents disbondment, ensuring long-term durability and reliable protection in harsh industrial environments

-

Safe: Cold-applied, 100% solids systems ensure safer application with no hot work, VOCs, or curing delays—keeping projects safety-compliant and operations running smoothly

-

Elastic Options: Flexible crack-bridging coatings maintain protection even if concrete moves or settles, preventing leaks, failures, and environmental contamination

-

Versatile: product range allows precise matching of coatings and mortars to each facility’s chemical exposures, operating conditions, and compliance requirements

-

Reliable: Proven track record in petrochemical, wastewater, power, food, and pharmaceutical industries—delivering consistent, cost-effective containment protection that customers can trust

Request a Secondary Containment Coating Assessment

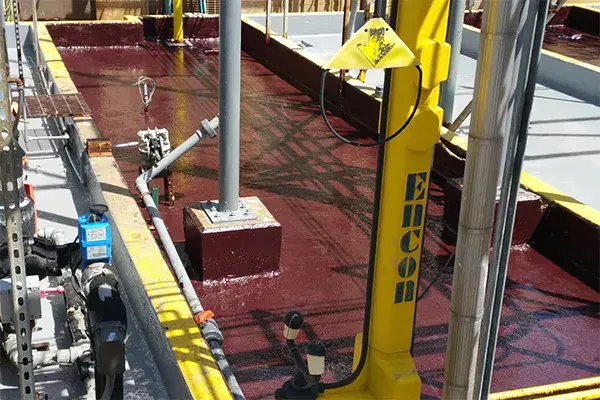

Sulfuric acid trough is lined with Belzona 4181 Magma-Quartz to withstand prolonged chemical exposure.

Why Plant Managers Trust BIG

Plant managers trust Banks Industrial Group for quick, cost-effective Belzona repairs that protect concrete against chemical attack and extend the service life of secondary containment structures without lengthy replacement downtime.

-

Tailored, Problem-Solving Approach: BIG collaborates with clients to deliver practical, cost-effective containment solutions—never overselling or applying unnecessary fixes

-

Proven Belzona Expertise: We use high-performance Belzona mortars and coatings that are fit for purpose, extending service life, and protecting your investment

-

Speed Without Compromise: Our cold-applied, fast-curing techniques minimize downtime, with most repairs completed in just days—not weeks—keeping your plant running

-

Versatile Repairs for Complex Needs: From occasional chemical exposure to constant immersion, BIG brings the right materials and in-house expertise to tackle the toughest coating challenges

-

Safety You Can Trust: With 100% of our team OSHA 30 certified and top-tier ISNetworld safety ratings, BIG ensures every job is done safely and responsibly

Restore Instead of Rebuild

Replacing crumbling containment areas can take weeks, cost hundreds of thousands of dollars, and shut down operations at critical times. BIG offers a smarter option: restore what you have. Our Belzona repair mortars rebuild eroded floors, spalled walls, and weakened sumps with exceptional compressive strength and impact resistance. Once restored, we seal the surface with chemical-resistant epoxy coatings engineered to withstand everything from splash-and-spill conditions to full immersion in concentrated acids and caustics.By extending the life of deteriorated structures, our solutions save clients money, reduce downtime, and buy valuable time to plan for eventual replacement on their terms—not under emergency conditions.

Concrete deterioration prepped for repair.

Repair mortar used to backfill damage.

First layer protective coating is applied.

Final coat resistant to concentrated acid.

Containment wall cracks sealed with specialized Belzona 2211 elastomeric which can withstand expansion and contraction movements without loosing its bond.

Comprehensive Containment Protection

Every project begins with a detailed site evaluation to identify the chemicals involved, exposure conditions, and structural issues. From there, BIG’s trained technicians restore the concrete, seal joints and cracks, and apply the correct protective system to match your environment. Belzona coatings offer outstanding adhesion, crack-bridging flexibility, and proven resistance to aggressive chemicals such as sulfuric acid, nitric acid, hydrochloric acid, and caustic soda—even at elevated temperatures.Because our materials are cold-applied, 100% solids, and solvent-free, application is fast, safe, and environmentally responsible. In many cases, containment areas are walk-on ready in just hours and fully resistant to chemical exposure within days—far faster than traditional concrete work.

Non-porous Belzona 4131 Magma-Screed epoxy mortar is used to repair an area of concrete deterioration where chemical resistance is required.

Extend Service Life, Reduce Costs

Restoration is more than a patch—it’s an investment in longevity. By rebuilding damaged concrete and adding a chemical-resistant barrier, BIG helps clients extend the service life of their existing assets, often by many years. This not only reduces the frequency of major capital projects but also prevents unexpected shutdowns caused by sudden failures. Many clients use our containment restoration services to bridge the gap between today’s repair and a scheduled replacement years down the road, ensuring safe, compliant operation in the meantime.Safety, Compliance, and Peace of Mind

Secondary containment is not optional. Regulatory agencies require proper upkeep, and failures can lead to heavy fines, costly cleanup, and legal exposure. BIG helps you stay ahead of compliance issues with durable repairs and protective systems proven in some of the most demanding environments. Our safety-first culture ensures every project is executed with care, precision, and full respect for your workers and facility.

This sodium hydroxide tank bund at a Delaware chemical plant has been freshly coated with Belzona 4311 Magma CR1 to protect against aggressive chemical attack. A non-slip aggregate was added for worker safety.

Restored concrete drum pad with chemical-resistant Belzona protective coating.

Proven Results

BIG has helped facilities across the region restore critical containment systems without costly rebuilds. We have rebuilt tank farm bunds, coated acid channels, sealed leaking sumps, and applied crack-bridging protective systems that keep containment areas secure despite ongoing slab movement. In every case, our clients saved time, reduced costs, and gained peace of mind knowing their facility was protected and compliant.Ready to Protect Your Secondary Containment?

Don’t wait for minor deterioration to become a major problem. BIG’s secondary containment repair and coating services can restore your structures, extend their service life, and shield your facility from costly chemical damage. Request a Containment Assessment today, or let us match the right Belzona specification to your chemical environment. For more information please call 856-687-2227 or email our secondary containment coating experts today for a fast quote.