Composite Wrap Pipe Repair Service

Banks Industrial Group delivers fast, expert composite wrap pipe repair solutions using Belzona SuperWrap II technology to extend the life of your critical infrastructure. Our highly trained, safety-certified field technicians rapidly assess damage to apply an appropriate cold-bond, high-strength epoxy and fiber wrap system that will restore the integrity of corroded, holed, or weakened pipes, tanks, and vessels—eliminating hot work and costly downtime. With deep technical expertise, we tailor solutions for thin-wall and through-wall defects, ensuring durable, corrosion-resistant repairs in extreme environments. Our engineered solutions comply with ASME PCC-2 and ISO 24817 standards, making them a reliable alternative to welding or pipe sleeve repairs. Contact us today for rapid, reliable service.

What We Like About Belzona Superwrap II Composite Repair

-

Minimizes Downtime – Cold-applied repairs provide an alternative to welding, reducing operational disruptions and often eliminating the need for costly shutdowns

-

Complies with Industry Standards – Engineered to meet ASME PCC-2 and ISO 24817 standards, ensuring quality, reliability, and DOT regulatory compliance – repair work done by validated personnel

-

Superior Strength – Superwrap II is one of the strongest composite pipe wrap systems available; it's tensile shear adhesion increases over time ensuring durable pipe reinforcement

-

Extends Pipe Service Life – Superwrap II delivers a durable, engineered repair solution, minimizing costly replacements and ensuring long-term reliability

-

Adaptability to Complex Geometries – Repairs pipe straights, bends, tees, flanges, valves and nozzles not suitable for pipe sleeves or clamps

-

No Hot Work Required – Unlike welding, Belzona’s composite solutions are cold-applied, reducing fire hazards and improving workplace safety

-

Designed for Harsh Environments – Withstands aggressive chemicals, high pressures, and extreme temperatures from -76°F to 302°F

-

Surface-Tolerant – Specialized composite wrap is available for repairs in damp, wet, and underwater environments without requiring abrasive blasting

Need Composite Pipe Repair?

BIG composite repair validated field technicians apply carbon fiber pipe wrap.

BIG's Composite Wrap Pipe Repair: What to Expect

Our crews are validated personnel, ready to restore structural integrity and repair corrosion, thin-wall and holed conditions for pipes, tanks and vessels. You can expect work to proceed at a fast pace and in a safe manner. Most repairs are completed in hours or days. In many cases, systems remain online without need for draining and clean-out, saving you time, money and labor.

- First, we assess the damage and match a solution appropriate to your operating environment and expectations

- We then, clean and prep the surface, which could include grinding and abrasive blasting to remove failed coatings, rust and debris

- If needed, we repair areas of metal loss, pitting and holes with a suitable Belzona Super Metal epoxy paste

- Next, we apply fiberglass or Superwrap II carbon fiber wrap and specialized epoxy resin that is fit for purpose to repair damage and restore structural integrity

- After curing, we will apply protective coatings when needed to shield against UV, heat, moisture and/or corrosive chemical exposure

- If insulation was removed, we will re-insulate pipes or tanks

Composite Pipe Wrap Repair Examples

The images below demonstrate a variety of composite wrap metal repair applications including: pipes suffering from corrosion under insulation, storage tanks with through-wall corrosion damage, repair of complex pipe bends and other industrial machinery.

Before: Pipe corrosion is difficult to repair in the area of valves.

After: We used Superwrap composite to restore pipe wall strength.

Corroded Fire Water Pipe Repair

This corroded fire water pipe at a pump station was fixed in just one day. Superwrap is ideal for challenging spots like this, where the presence of valves, tees, and bends makes using pipe sleeves impossible. In this scenario, how long would a weld repair require?

Before: Fiberglass cooling tower beetle pipe break during cold weather.

After: Emergency pipe wrap repair and protective coating completed in 36 hours.

Fiberglass Pipe Break Emergency Repair

This fiberglass cooling tower water pipe unexpectedly broke due to cold weather. Utilizing the swift repair capabilities of the Superwrap system, we managed to initiate an emergency response and fix the damage in just 36 hours. Discover more in our case study here.

Before: Water drips from process water pipe leak at failed weld seam.

After: Weld seam pipe leak repaired with carbon fiber composite wrap.

Weld Seam Leak Repair At Pipe Curve

This process water line experienced a gradual leak due to a failed weld seam. The repair was complicated by the pipe's complex curvature. Luckily, Superwrap adapts to bends, tees, flanges, and irregular shapes, allowing us to quickly seal the leak and reduce the risk of a plant shutdown.

Before: Active leak sprays water from this pumping station pipe.

After: Pipe repaired with Belzona metal rebuild and composite pipe wrap.

Water Pumping Station Pipe Leak Repair

We quickly addressed the leak at a water pumping station in the Philadelphia area by utilizing Belzona metal rebuilding paste to repair metal loss and applying Superwrap II carbon fiber pipe wrap to enhance and restore structural integrity, ensuring a dependable, long-term solution.

Before: Severe corrosion under insulation affecting this process vessel wall.

After: Superwrap restores structural integrity to damaged process vessel wall.

Process Vessel Corrosion Under Insulation Repair

The corrosion concealed beneath the insulation of this process vessel at a petrochemical plant advanced to a stage where the walls became thin and perforated. We addressed the metal loss by applying Belzona Super Metal paste and strengthened the side walls using a carbon fiber and epoxy resin Superwrap composite repair.

Before: Exchanger shell with holed conditions due to corrosion damage.

After: Superwrap was used to repair and strengthen corroded exchanger.

Holed Exchanger Shell Repair

This heat exchanger shell at a Pennsylvania chemical plant developed holes due to corrosion. We applied Superwrap to fix the damage and swiftly restored it to service, reducing the facility's downtime.

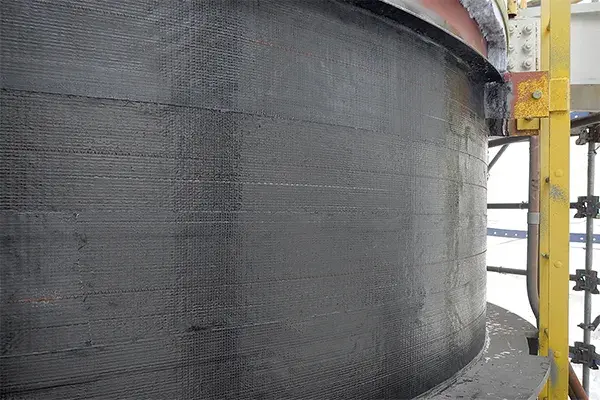

Before: Tank wall suffering from severe corrosion and holed conditions.

After: Repaired with Superwrap carbon fiber and epoxy resin composite wrap.

Holed Tank Wall Repair

At a chemical processing facility, we utilized Belzona Superwrap II to mend and reinforce the damaged wall of this tank. Superwrap is a specialized repair solution designed to prolong the lifespan of important equipment.

Before: Corrosion under insulation created a thin-wall condition weakening the pipe.

After: We applied Superwrap II in-situ to restore pipe strength and reliability.

Corrosion Under Insulation Pipe Rehab

Corrosion under the insulation of a cooling tower pipe at a NJ university weakened it, risking breakage and shutdown. Belzona Superwrap II was used on-site to reinforce the pipe without interrupting operations.

Before: Corrosion of this economizer created a thin-wall condition.

After: Corrosion repaired with Superwrap and protective coating.

Chiller Economizer Repair

Corrosion thinned the pipe walls and shell of this chiller economizer. To restore structural integrity, we applied Superwrap, then protective coatings to prevent future corrosion. Given the high cost, long lead times, and challenging accessibility of these components, Superwrap offers an effective solution.

Before: Corrosion under insulation damaged this chiller suction elbow.

After: Superwrap composite easily fit the elbow to restore structural integrity.

Chiller Suction Elbow Corrosion Repair

The suction elbow of this water-cooled chiller suffered damage from corrosion under insulation, caused by pipe sweating near the flanges and insulation joints. We applied Belzona Superwrap II to restore its structural integrity and added protective coatings to prevent future moisture damage.

Before: Chiller evaporator inlet with corrosion under insulation damage.

After: Superwrap easily fits this complex shape for a fast, in-situ repair.

Evaporator Inlet Corrosion Repair

The inlet of this water-cooled chiller's insulated evaporator heat exchanger experienced corrosion because of condensation trapped under the insulation. We applied Belzona Superwrap II to fix the damage on-site. Superwrap enabled a quick repair due to its capability to handle complex shapes.

Before: Wastewater pipe severely eroded by dripping water and chemical attack.

After: Restored with Belzona Super Metal and Superwrap composite wrap repair.

Eroded Wastewater Pipe Repair

Persistent water leakage and chemical exposure led to significant erosion of this wastewater pipe at a treatment plant in New Jersey. We implemented a swift solution by utilizing Belzona Super Metal epoxy paste to rebuild the metal loss and Superwrap II to reinforce strength and structural integrity.

Before: Misaligned cooling tower header pipe created a weak area prone to failure.

After: Misaligned cooling tower header pipe strengthened with composite wrap repair.

Misaligned Cooling Tower Header Pipe

The misalignment in this cooling tower header pipe formed a vulnerable area that could potentially fail and cause a shutdown at a New Jersey gas turbine power plant. To address this, we applied Belzona epoxy paste and Superwrap as a permanent solution to reinforce the joint and enhance the reliability of the cooling tower.

Before: Earlier pipe clamp repair exhibiting signs of wear and imminent failure.

After: Pipe clamp substituted with dependable carbon fiber Superwrap.

Failed Pipe Clamp Repair

The old pipe clamp repair on this cooling tower pipe was swiftly substituted with a Belzona Superwrap II composite repair to prevent failure. Superwrap is an engineered solution that restores pipe-wall strength for dependable, long-term service.

Before: Tank wall perforations rendered this vessel unusable.

After: Restored to operation with metal rebuild paste and composite wrap.

Small Oil Tank Patch Repair

This small oil tank became unusable due to holes in its wall. To fix this, Belzona metal rebuild paste was applied to mend the holes, and Superwrap carbon fiber composite wrap was utilized to reinforce the structure and bring the tank back into operation.

Emergency Pipe Break Repair Case Study

Read about how BIG used Superwrap II for the emergency repair of a ruptured cooling tower pipe at a NJ power plant, restoring operations in 36 hours.

Superwrap II Specifications

*All properties are to be used as a guide only. Please check with your BIG representative for specific information.

We stock Belzona 9381 glass / carbon fiber hybrid sheet ready for repair work.

Belzona 1981 Superwrap epoxy resin.

BIG Provides Rapid Composite Wrap Pipe Repair Service

Banks Industrial Group provides expert repair service for corroded, thin-wall and holed industrial pipes and infrastructure. We design repair solutions that fit the site requirements and operating conditions of our clients. Our field technicians are validated composite repair personnel who bring a strong work ethic and commitment to safety to each project. We work efficiently – minimizing downtime for repair work, and getting your operation running again as fast as possible. Trust BIG to cover your pipe repair needs! Call 856-687-2227 or email our composite pipe wrap repair experts today for a fast quote.